Overall Labour Effectiveness: Improving Profitability Through Productivity Part Two

“If you don’t measure it, you can’t improve it.”

Following our first article on Overall Equipment Effectiveness (OEE), we will explore another key performance indicator for productivity: Overall Labour Effectiveness (OLE) – a much more people-orientated metric.

Like OEE, and, in line with Lean principles, OLE seeks to define and quantify how productive business operations are, with a view to identifying and removing wasteful activity, or at least activity the customer does not value. However, unlike OEE, OLE concerns people not equipment so a different approach is required when deploying it as well as careful consideration of where investment in digital and AI solutions can help.

OLE is more effective when used as part of a wider management system to improve performance, Typically this would include management and staff collaboration, mindset and behaviour changes, coaching, process changes and leadership resilience to make change ‘stick’. Additionally, OLE can be deployed in any industry sector, business function and at any organisational level, although its use can be a little more subjective as it involves evaluating the ”importance” of different tasks, or at least the extent to which tasks help to generate value in the eyes of the customer.

OLE can be improved significantly by digital and AI solutions by taking on data extraction, monitoring and analytical tasks that might otherwise take humans hours or days to process. Examples of this include machine performance monitoring (links to OEE), contract analysis, dealing with customer queries, invoice processing, initial reviews of CVs or even reconciling sales, operations and supply chain data sets to identify trends/risk and accelerate strategic decision making. Start-ups and high growth organisation have the advantage in that they can fully integrate these solutions into their operations from the outset and as part of an initial large capex outlay rather than retrofitting solutions into well establish operations (the latter typically benefit from more targeted solutions). This means staff take on more of a design, improve and maintain role rather than one of day-to-day operator.

While a continuous improvement philosophy is commonly associated with manufacturing and production organisations, service-based businesses can also benefit from the continual scrutiny of their day-to-day operations to enhance productivity, quality and customer delivery. This is where OLE comes into play. By tracking and acting on OLE metrics, organisations can manage growth with their existing team size.

Knowing that people, supported by technology, are the driving force behind a company’s performance, and that true performance transformation can be tough, A&M’s Operations and Supply Chain team works with all stakeholders – from front line operators to back-office support staff – to support them through transformation and deliver tangible results quickly. Here’s what we know works.

Why OLE matters

Increasing productivity is one of the best ways Operations can contribute to the P&L. Improving productivity is often mis-understood as simply working harder. In actual fact, reducing wasteful activity and inefficient processes means less mistakes and rework. This in effect creates capacity to do more of the right activity. To understand this better we should define what OLE in more detail.

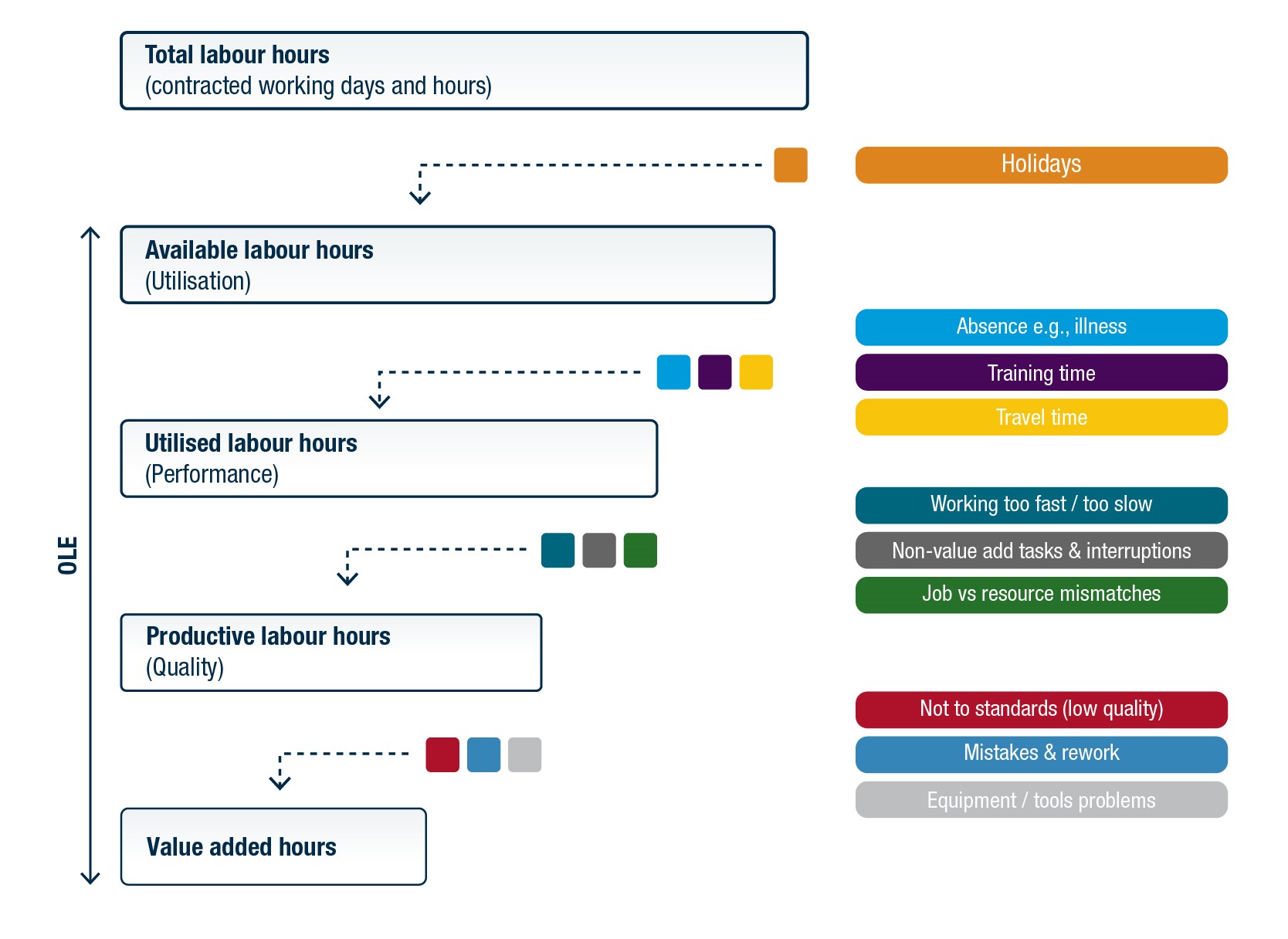

Like OEE, OLE can be split into three main components:

- Utilisation i.e., actual time spent in the workplace working on value-add tasks;

- Performance i.e., processing rate an employee can work at;

- Quality i.e., mistakes made or tasks completed that are not to standards.

OLE = value-add hours / available labour hours

OLE helps to:

- Relate all office / shop floor / team activity back to what the customer actually wants i.e., ‘Would the customer be happy about paying for this activity?’;

- Identify what activity is still necessary to help run the business vs. what can be reduced, stopped, outsourced or automated;

- Inform what action to take and where and relate this back to business results;

- Improve service quality and outcomes without having to significantly increase costs.

It therefore helps to make links between unproductive staff time and P&L costs.

So what does good look like?

Companies that use OLE or similar approaches typically have:

- An acute appreciation of the importance of scrutinising day-to-day tasks at all levels of the organisation and continually asking “how can we do this better?”;

- A leadership team that values its staff and prioritises engagement, focusing on understanding how employees work and how they can be supported to succeed in their roles. This includes a strong emphasis on coaching, support and investment in staff development.

- A leadership team that is open to discuss how to link staff performance to well-being, recognition and reward;

- A “Growth Mindset,” where both management and employees recognise the need for performance measurement and associated dialogue i.e., staff being open to discussing whether they could do things differently;

- Consensus on what is a suitably ambitious level of performance to aim for;

- A desire to explore how digitalisation and AI can help automate repetitive tasks and providing meaningful insight to help make important decisions;

- An OLE champion who understands how to explain and use OLE technically and appreciates the “human” side of deploying it successfully.

As seen, OLE is a much more people and behaviours orientated method for improving productivity as it concerns arguably the most complicated part of a business to manage – people! We can all remember what it was like to receive feedback and performance scores at school and as children we generally embraced this well. As adults in the workplace, however, this becomes much harder, especially if performance-related discussions are not well handled. This dynamic and associated psychology needs to be considered from the outset.

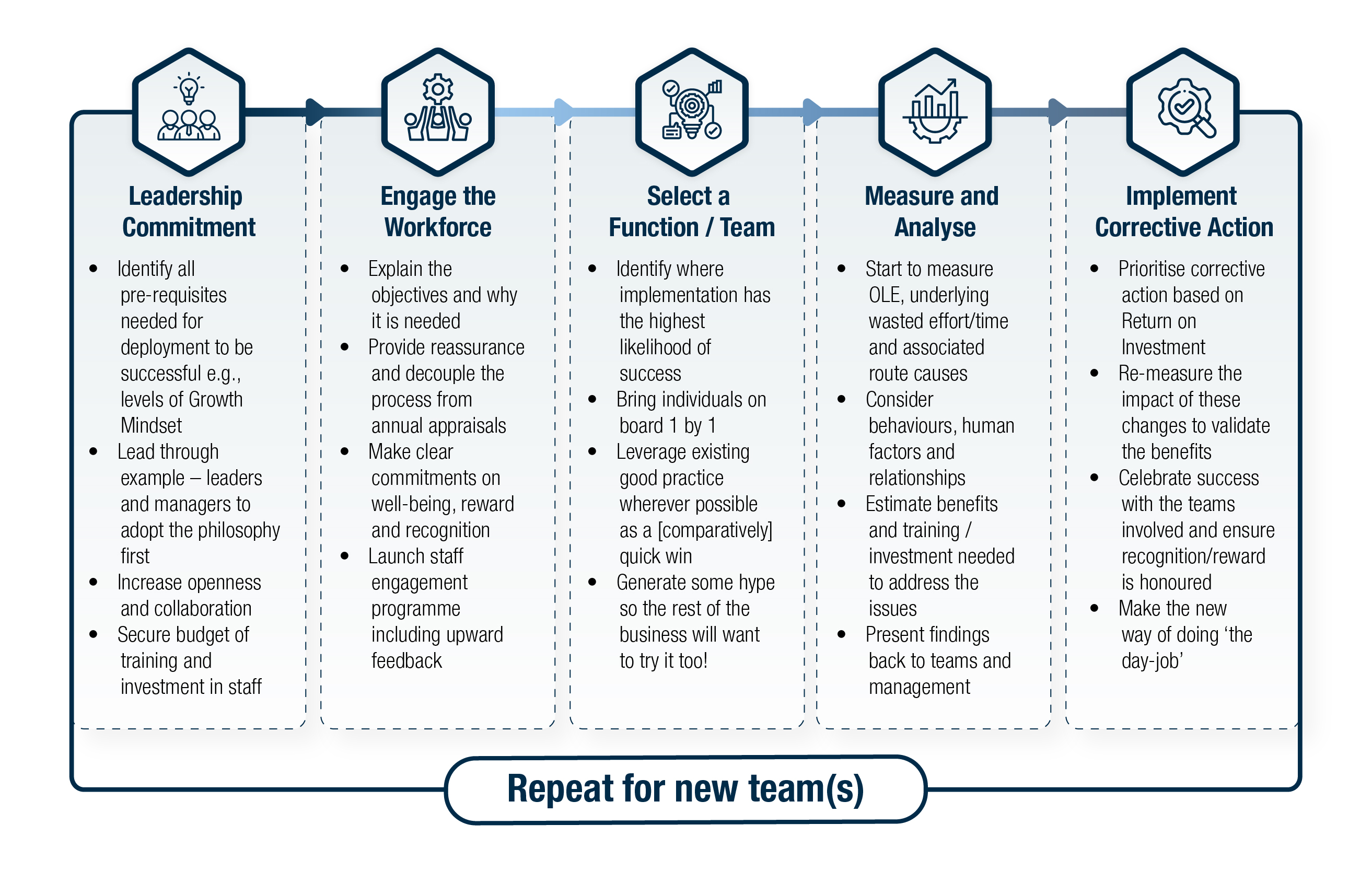

How to implement OLE:

Here are some of our top tips for making OLE work:

- Agree a team vision: Whether it’s a target, an outcome or a result, giving the whole team a sense of purpose and something tangible to work towards is a powerful driver of performance, helping everyone to align and encouraging mutual support;

- Focus on behaviours: Talking about individual and team performance can often be a significant cultural challenge. Therefore, business staff may need coaching and support to embrace talking about both successes and areas that need improvement;

- Don’t take it literally: A metric like OLE is simply a “north star” towards finding ways of improving the day job. The value comes from establishing a better culture of performance scrutiny – whether someone spend 15 minutes per day too long on excessive report writing or otherwise is not so much the priority.

- Coach and support: Coaching means guiding staff without direct intervention. Support is rolling your sleeves up and helping. To make the use of OLE effective, staff need both at the right time. Line managers must put significant effort and time to deliver on these; they also need coaching and support themselves to ensure they are equipped with the right behavioural skills;

- Focus on Right First Time: In the early stages, maximising deployment success and getting it right first time is the priority. The results will soon follow. Ideally staff involved will start to promote the initiative to their peers once they see the benefits to them. This helps to generate a “buzz” around the business which will make future deployments easier;

- Articulate the benefits: OLE typically results in less wasted time and effort, as well as better work outcomes, but this needs to be equated to either an increase in available capacity or, depending on the business context, a reduction in direct costs. It may also help to improve service quality (as measured by the customer).

OLE in practice

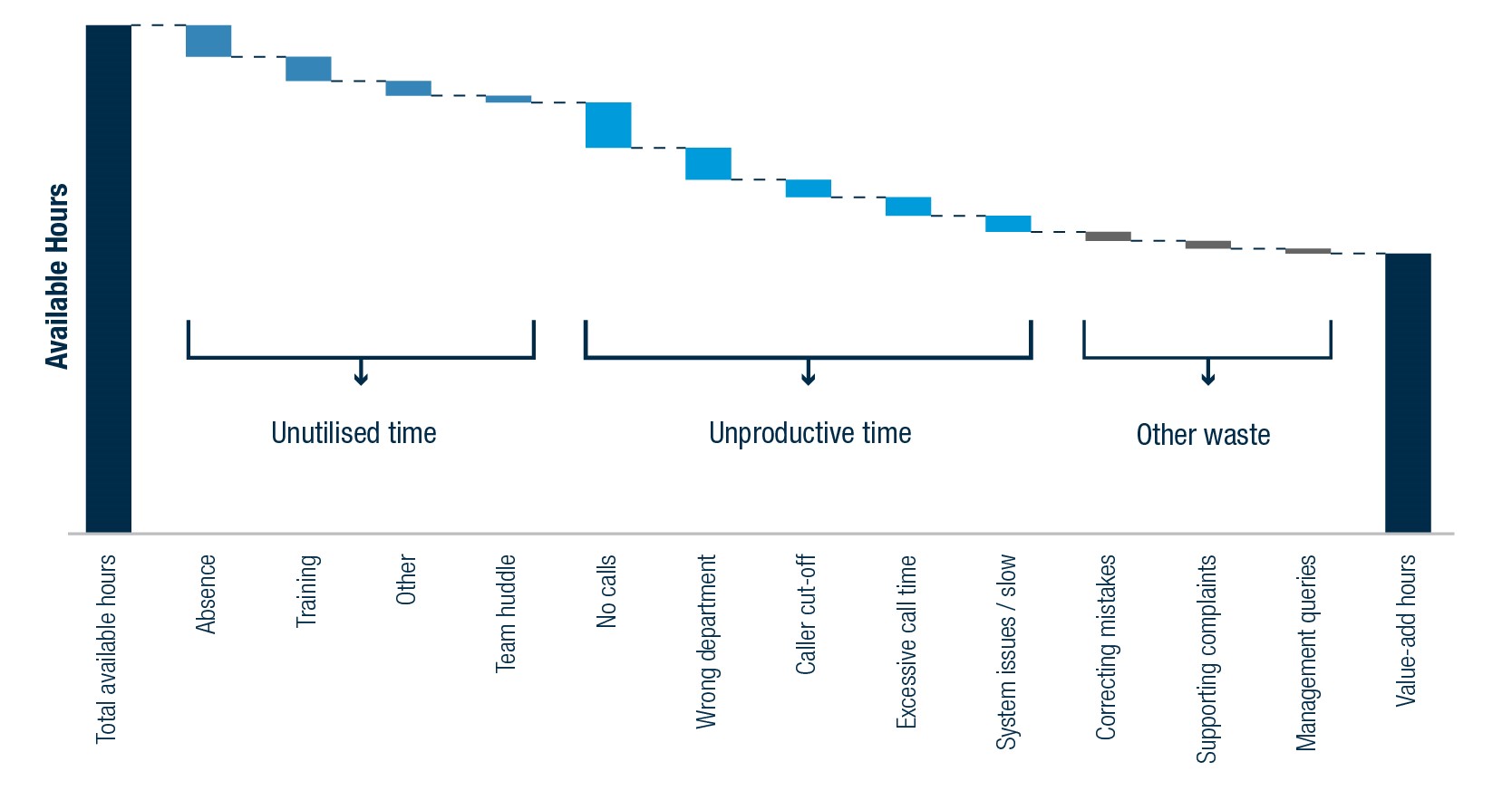

In this illustration, an OLE coach worked with a call handler in a call centre who was complaining about “system problems” being the route cause of most of their day-to-day issues. The coach worked with the individual to understand their role in relation to what the customer was paying for, their day-to-day activity, stakeholders and data they worked with, and what systems/tools/techniques they used. They walked the tasks in detail and, crucially, collaborated with other staff to understand the associated handoffs i.e., the “internal customer” philosophy.

A profile was established showing how their time was typically spent. The results showed that the highest instance of wasted time was due to not having any calls, suggesting a central planning and scheduling problem and/or imbalance between call demand vs. available staff. Absenteeism was also noted to be high (although typical for the rest of the team), suggesting coaching might be needed to bring overall levels down. Lost time from actual system issues (e.g., not switching off fully to clear the cache, deferred system updates) represented a comparatively small amount compared to other areas.

Because drivers of inefficiency in the “Other waste” category are necessary, even if they are not strictly value-add time, further analysis would be required to see if this time could be reduced rather than stopped altogether. This could be done by addressing the root causes of customer complaints and the knock-on inefficiency this creates. Other wasteful areas such as “Wrong department” need to be eliminated completely.

An area of particular interest is “Excessive call time,” which meant the average call time for the individual was higher than target (sometimes referred to as Takt time in a manufacturing context). Setting target time or work rates for well-defined tasks is an intuitive step for management to take to improve performance, however, implementation is difficult. Agreeing with staff what is a suitably ambitious target can easily result in disagreement and stress if not handled correctly. The emphasis must be on a) identifying and standardising good practice or expertise that higher performing staff are capable of (internal benchmarking of performance), and b) replicating this across the team, rather than focusing too simplistically on variance between target and actual task time and apparent “underperformers” (who may simply need training and coaching to improve).

In this engagement, the staff member’s work was typical of everyone in their team, so the results could easily be prorated up to help understand the aggregate impact of making improvement. Following this, a few metrics were put in place, using available system data and daily team huddles, to track progress against making improvement and generate new ideas.

How to take corrective action

- OLE analysis will help identify where the waste is, but more work is needed to identify the precise root cause and the consequent corrective action.

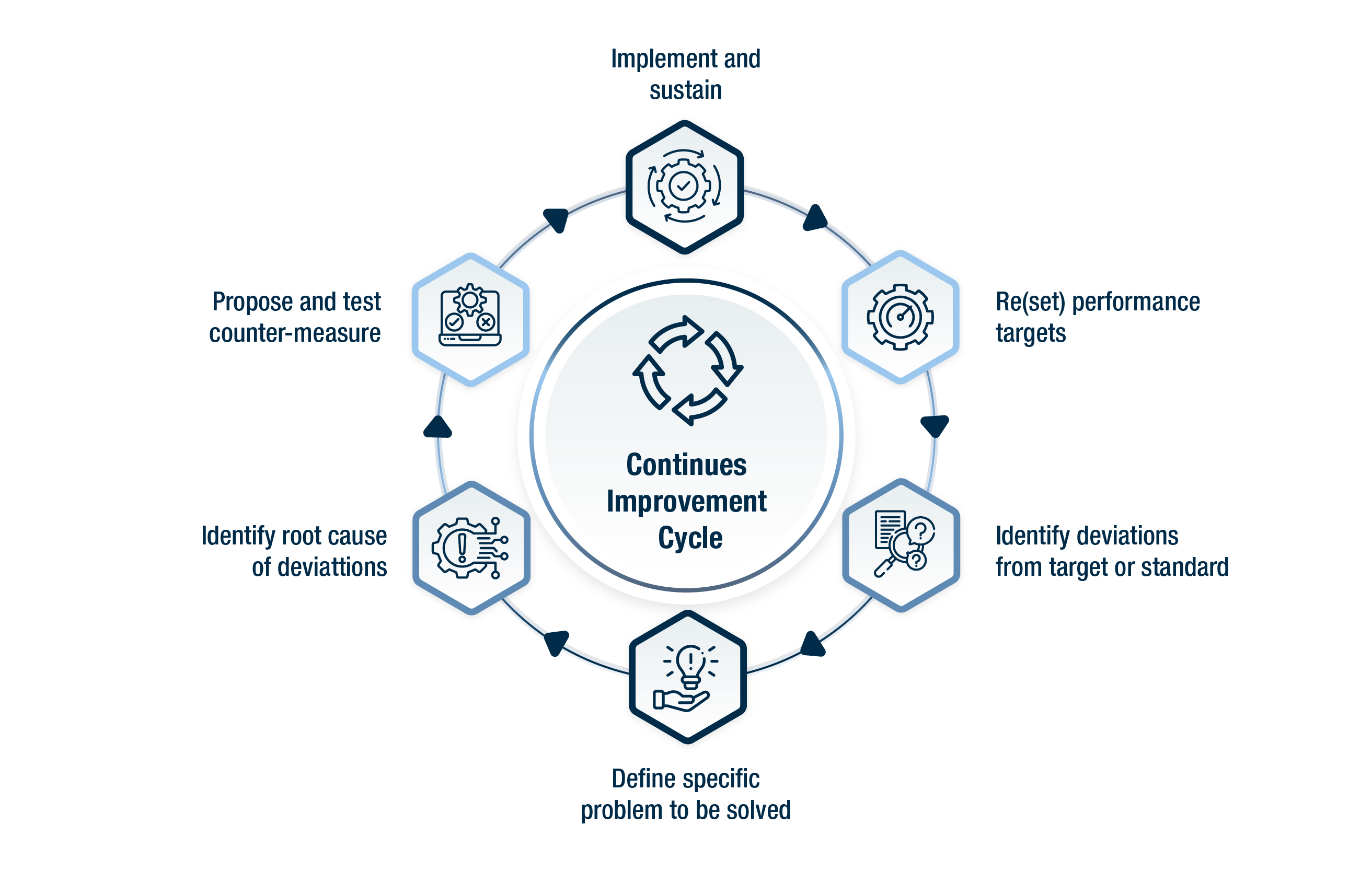

- A strong continuous improvement (CI) culture (Kaizen) is essential, as multiple actions will be required. While individually these actions may not be complicated, the volume can feel overwhelming for workers when there is so much “business as usual” to focus on already. This is where support is needed to make sure the right CI “drumbeat” is in place, and that the right skills are available to capture and report benefits, whether they are related to P&L or not.

- Remember, OLE is just one tool within a wider management system of performance improvement. The real impact on productivity – and ultimately P&L – comes from the follow-up actions taken based on the new insight OLE provides.

OLE can therefore be a powerful metric to help improve performance, particularly when used as part of a wider system of continuously seeking ways to reduce waste and improve performance.

The OLE metric should be used as part of a wider continuous improvement approach.

About A&M

Founded in 1983, Alvarez & Marsal is a leading global professional services firm. Renowned for its leadership, action and results, Alvarez & Marsal provides advisory, business performance improvement and turnaround management services, delivering practical solutions to address clients' unique challenges. With a world-wide network of experienced operators, world-class consultants, former regulators and industry authorities, Alvarez & Marsal helps corporates, boards, private equity firms, law firms and government agencies drive transformation, mitigate risk and unlock value at every stage of growth.

To learn more, visit: AlvarezandMarsal.com