Aligning Procurement Strategy with Overall Business Plans will Help your Company Compete

Digital technologies in procurement and supply chain management are developing at an increasing pace and accelerating efficiency gains throughout the procurement process. However, to realize the full potential of commercial optimization and to improve the company’s competitive position, it is necessary to build a compelling digital strategy that addresses the focus areas of the procurement plan, in particular, addresses the overall business strategy of the company.

To be competitive, procurement organizations need to cover three key areas when developing their digital strategy:

- How to create business value

- How to get necessary enablements in place

- How to build or integrate a solid data foundation

These building blocks can guide the development and execution of a digital procurement strategy that will not only help procurement departments to boost their own operational performance but also contribute significantly to the company’s overall strategy as a driver of transparency, budget control, collaboration and third-party integration.

Opportunities and Challenges Faced by Procurement Teams

Procurement organizations are facing major change through digital technologies. Significant improvements in computing power combined with emerging technologies such as robotic process automation (RPA) and artificial intelligence (AI) have created many new opportunities. Activities and use cases include:

- Running simple tasks such as invoice processing and reconciliation.

- More complicated activities in the areas of spend reduction and supplier risk management and monitoring.

- Real-time tracking across end-to-end supply chains to create ease and cost-efficiency.

But digital procurement is not just a buzzword. It is a target and procurement leaders need to deliver. The challenge is, many procurement organizations lack implementation of digital solutions in procurement and remain in the pre-digital past, which means many tasks are done manually with almost no automation, inefficient sourcing processes that are used and importantly, there is an overall lack of data transparency which leads to decisions without a comprehensive data basis.

The main question for leaders is, how can my business realize digital’s full potential in procurement? In fact, digital procurement requires more than switching some processes from manual to automated. Procurement organizations should rather build their digital strategy in line with the overall procurement strategy to strengthen and enhance their internal value proposition and to improve the company’s competitive position in the marketplace.

Leadership Plan for Executing a Strategic Procurement Function

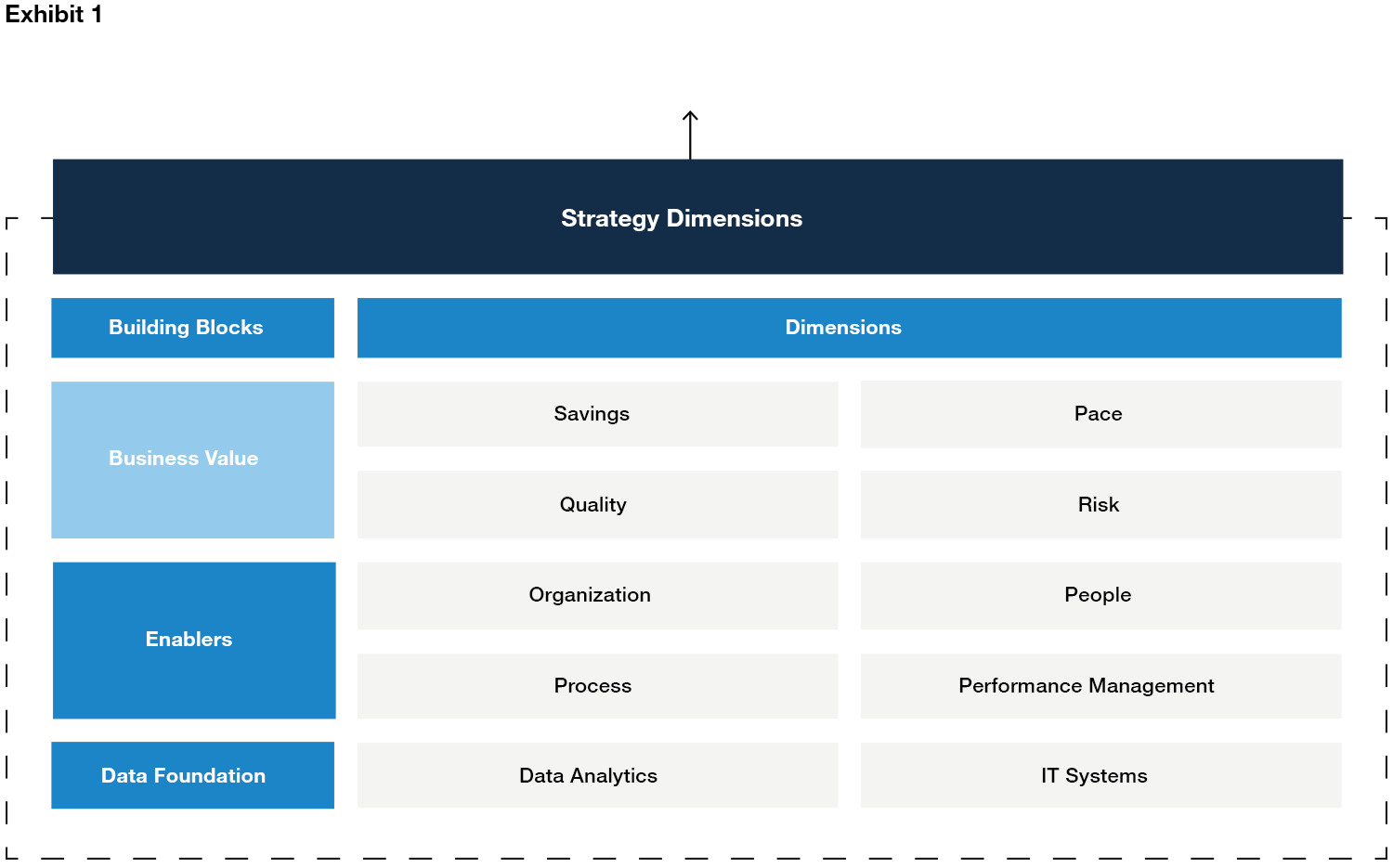

Three focus areas are key in every strategic procurement consideration (Exhibit 1).

Focus on creating business value. The digital strategy and toolset developed for the procurement function must support the focus areas of the overall procurement strategy.

Make sure that the necessary enablers are in place. Typically, the greater the procurement organization’s maturity, the more value the digital strategy can realize. However, significant changes in organization and processes are needed to realize the full potential of digital in procurement.

Build a solid data foundation. The core of a digital procurement strategy is the data foundation, which consists of new digital analytics and existing IT systems.

Dimensions of the Digital Procurement Strategy

1. Increase the procurement function’s contribution to the overall value proposition of the company

- Improve category-specific sourcing strategies

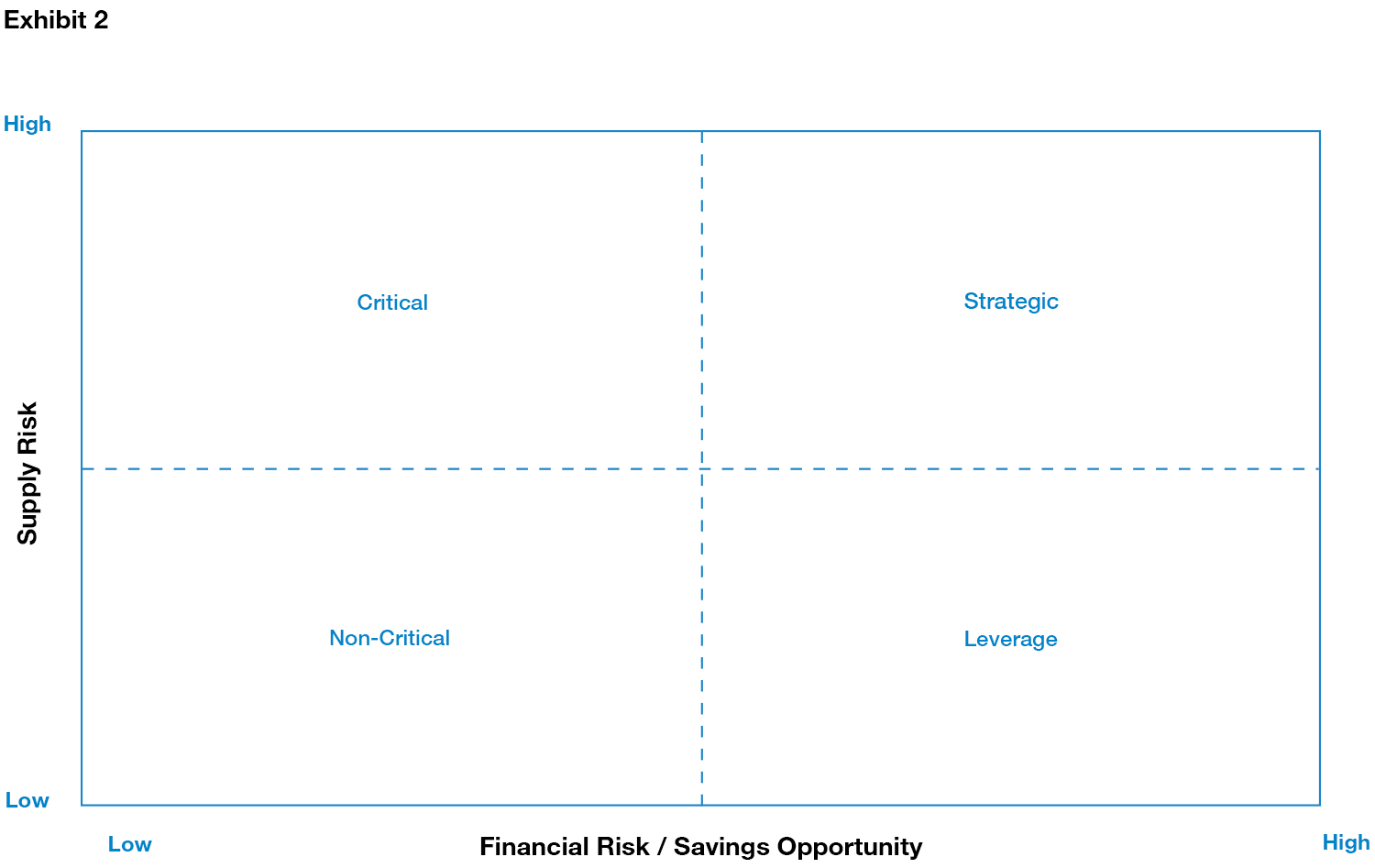

As for most procurement departments, savings are the most critical KPI to base their efforts on and will help to investigate opportunities for digital functions to support savings generation along with the categories of the Kraljic Matrix.

Strategic items

These items have the highest impact on business value. When sourcing such strategic items such as specific microchips or semi-conductors used in mobile phones, buyers typically benefit from close supplier relationships and in-depth knowledge of those articles.

To identify savings opportunities for high value items the application of should-cost models is a promising approach. Should cost modelling tools typically consider and track all inputs to the supplier’s product costs and build a comparison with the actual pricing for that product. Based on this dynamic analysis improvement opportunities on item level can be identified and prioritised.

For example, a manufacturer of compressors is using a "should-cost" model for specific key parts like pistons or crankshafts to automatically track cost of labour, logistics, raw materials and energy in a specific item to compare it with the actual price paid to the supplier. This allows the procurement team to understand supplier’s costs and margins as well as fluctuation of these measures. This knowledge helps to identify the right time to re-negotiate and to set ambitious savings targets without putting the strategic partnership at risk.

Leverage items

These items are a key area to drive savings and profitability as there is no, or only very limited, supply risk. To leverage the competitive situation and get the best pricing on these items, procurement should always deploy the best fitting tool for the specific situation. This can range from e-auctions to smart analysis tools for requests for quotation (RFQ) or price regression models when preparing for face-to-face negotiations. But reality and project experience shows that many procurement departments use the same approach repeatedly at the cost of effectiveness and efficiency.

Digital procurement technologies can help. As a starting point, get a ready-to-use e-procurement suite including e-auctions and RFQ templates and a well-equipped procurement toolbox with should cost and price regression models in place. An algorithm-based tool, which analyses different parameters, like price transparency, competition, etc., to select the best approach for a specific situation can be implemented to enhance efficiency.

Take, for instance, a large manufacturing company that asked for support to tender its whole European road freight network. Through a digital sourcing platform an RFQ with over 2.500 unique lanes was issued to over 100 potential service providers. After two bidding rounds, the client ended up with an ideal scenario generating double-digit savings while maintaining service levels on all lanes.

Non-critical items

This is typically your tail spend consisting of a large number of C-Parts. There is often little transparency and active spend management for these items in procurement departments. Hence the challenge here is to source your tail spend as (cost) efficiently as possible, which offers great cases for digital procurement.

Consider the following business scenarios that would benefit from digital procurement solutions:

- Digital-tendering solutions - In a pre-digital environment, companies often were not able to tender their tail spend and C-Parts efficiently due to a lack of data transparency. With the help of digital tools, this is no longer the case as there are applications that can automize data extraction and evaluation from different sources. Building on this database digital tools provide buyers with the opportunity to include thousands of items in one tender where suppliers see only the items they can provide. This leads to a significant reduction of complexity of the tender process on both ends and hence motivates more suppliers to bid and encourages buyers to tender even tail spend categories on a regular basis.

- Think, for example, of your typical MRO spend, which is often highly fragmented and split across many suppliers as a result of historical development and a lack of transparency. In a recent project, we were asked by an industrial client to support an MRO procurement initiative. With the help of a digital tendering solution and integrated data analytics, it was possible to gain transparency on all items purchased by the different units from different suppliers to build a solid baseline. In a next step, a tender was issued to a broad and competitive supply base ending up with a harmonized item portfolio and a consolidated supply base generating savings in a double-digit range.

- Heat maps - Utilizing digital tools buyers can build sourcing heat maps for their categories, which provides an easy way to determine where suppliers are located, the number in each geographic area, and at what average costs. Based on that information, procurement is put in a position to be able to tailor each auction and RFQ to meet the supply characteristics of the geographic location being targeted.

- E-catalogs - C-Parts and standard items can be consolidated in online or punch-out catalogues, which are accessible through the company’s ERP-System. In a simple process, users select items they need to purchase and can transfer their selection directly in a purchase order (PO) for the pre-defined preferred supplier while ensuring compliance with product standards.

- Critical Items - These items are critical to the business and associated with high supply risks. Thus, priority is to secure existing supply and to build and expand new ways of sourcing.

- Digital solutions such as e-sourcing platforms can help by quickly and comprehensively scanning the market with standardized and efficient RFI management for bottleneck items.

a) Increase Pace of Procurement Processes

There are basically two main processes, which define the pace of a procurement organization:

- Sourcing of a new product or from a new supplier (source to contract)

- Transferring a purchase requisition to order at the supplier (PR to PO)

On the first, more strategic process, digital tools can help significantly to conduct faster and more accurate analysis. Typical use cases are automated RFI and RFQ management through an e-sourcing platform while more advanced applications could include algorithm and AI-based negotiation and supplier selection tools.

But digital tools can be especially helpful in the multistep PR-to-PO process. Typically, this process requires a lot of manual tasks done by operational procurement employees.

Robotic process automation (RPA) can help cut the time significantly for converting a purchase requisition (PR) to a purchase order (PO). RPA seeks to streamline processes and reduce time spent by:

- Providing customized requisition formats for the product or service being purchased

- Progressing the exact approval and ordering steps along a defined process for multiple buying channels and different category groups

- Automatically filling out POs with relevant product and commercial information

- Checking the inputted information and transmitting POs directly to the supplier

b) Utilize preventive and reactive tools to enhance risk management

Companies expect the procurement function to avoid risks to supply chain continuity and environmental sustainability. Digital tools that help to decrease these risks can be separated in either preventive or reactive.

- Preventive digital tools:

These tools help your company to identify risks that are likely to occur and predict their occurrence probability to prioritise mitigation measures. For example, this can be the supplier’s risk of running into bankruptcy and disruption of supply. Digital solutions are capable of combining financial data, current market developments and internal supplier audits and quality reports to a consolidated real-time risk measure.

- Reactive digital tools:

Reactive tools prepare your procurement department to be able to respond quickly to existing risks. Most importantly this covers contract management systems. Digital contract management tools keep all contract parameters up to date and available in one single source of truth. They are also capable of tracking all changes and steps of the approval processes. This helps buyers to always be aware of their contractual position and to implement mitigation measures once a risk occurs.

c) Make use of your data to ensure efficient quality management

Procurement quality means delivery of procured goods and services in the right specification at the right time in the right place. Maintaining these quality levels in global supply chains has become a critical concern.

Digital tools can support quality management from a procurement point of view by highlighting past quality issues and respective cost impacts on category or even item level. This data can be used to develop a preventive system that shows areas with a high likelihood of failures to identify requirements and scope for supplier audits or other preventive measures.

This can be supported by a digital quality assessment of goods received and real-time feedback to the procurement department through mobile apps.

2. Enable the procurement organization to deliver sustainable results

The second focus area of the strategic plan is the installation of enablers. Procurement leadership needs to develop a clear understanding regarding which enablers are most important for the value dimensions which are prioritized in their procurement strategy. Hence, technology considerations should always follow strategic priorities when deploying different enablers. Typically, there are four types of enablers: organization, processes, people, and performance management.

a) Organization

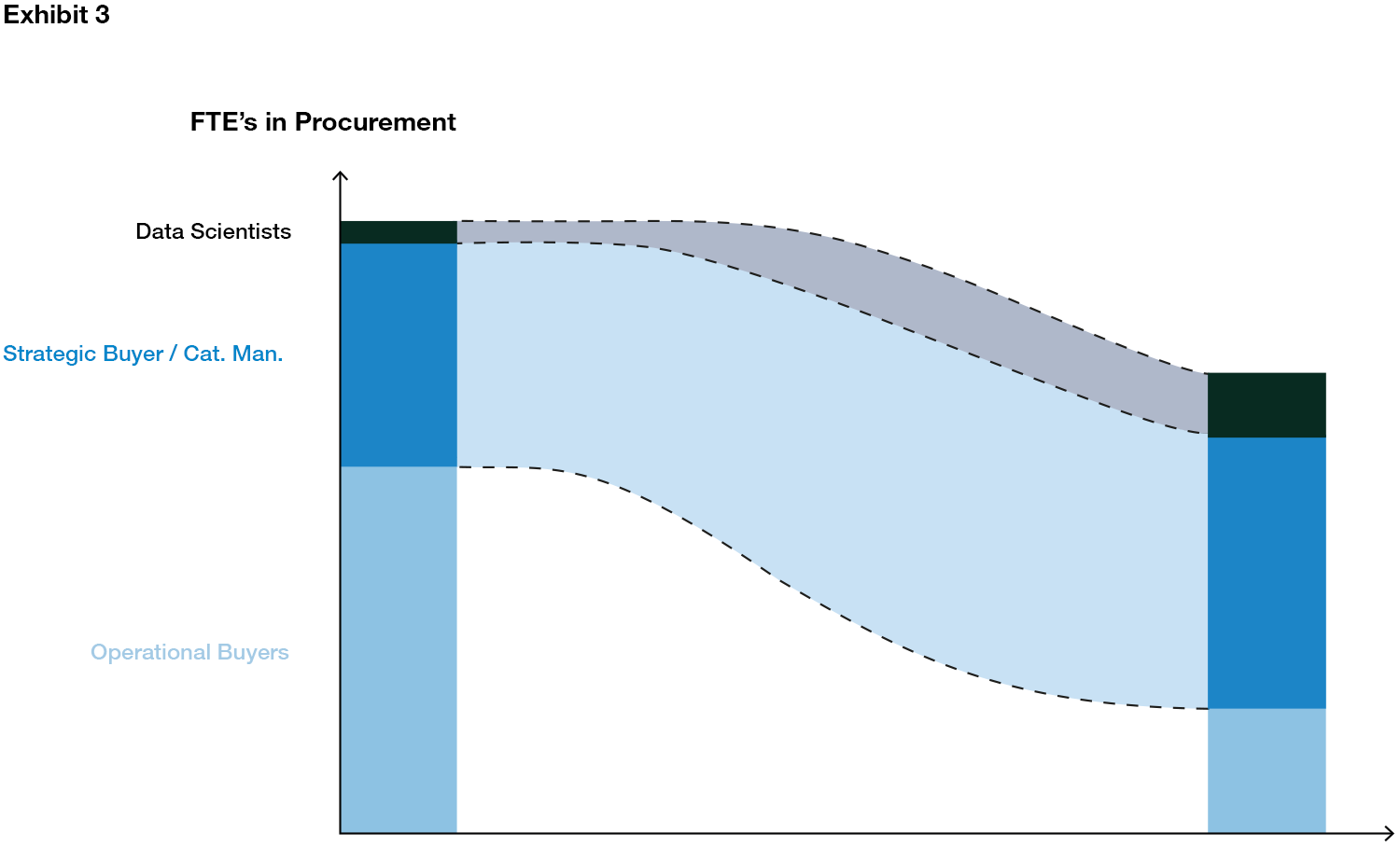

The digital procurement organization will significantly differ from what we are used to seeing in the pre-digital past. There will be a fundamental change in roles and required skill set due to digital technologies. Also, procurement organizations will likely shrink in overall size but deliver higher value to the business (Exhibit 3).

Procurement teams will primarily be responsible for the following functions:

- Tactical and operational buyers: A significant proportion of the repetitive tasks can be performed by robotic process automation (RPA) and artificial intelligence (AI) applications.

- Strategic buyers and category managers: In the short and medium-term, real strategic activities, such as developing category strategies will be less impacted by digital technologies will. But strategic buyers will need to upskill their digital capabilities as typical tasks like consolidating data sets and conducting basic analysis such as linear performance pricing (LPP) or price regressions will be fully automated. In addition, AI-based technologies will become important to help procurement in negotiation preparation and supplier selection processes.

- Data scientists: The digital procurement organization will create the need for new roles like a central master data management and advanced analytics team.

b) Processes

We split the procurement process into three sub-processes:

- Planning-to-strategy (P2S)

- Source-to-contract (S2C)

- Procure-to-pay (P2P)

While there will be only little impact on P2S, we will most likely see major changes in S2C and P2P processes. All types of digital technologies will play an important role in transforming these processes with AI having the biggest impact on S2C (e.g. help buyers make the best decisions for maximizing savings) and automation playing the largest role in the P2P process (e.g. automated order-processing solutions for tailored buying channels).

c) People

Digital solutions will not only enhance direct value delivery but can also facilitate capability development with online assessments and customized courses. As the new technology landscape requires employees to significantly adapt and enhance their skills, this should be a major focus for procurement leadership.

d) Performance management

Typically, performance management systems provide:

- The set of relevant KPI’s to determine and communicate performance of the procurement function

- Measures of individual contribution to the overall targets (on department, category, and individual level)

As performance management systems can be used to support all value dimensions, it is important to target the dimensions deemed most important. Digital tools are making a significant difference in what performance management can deliver including:

- KPIs that can be drawn automatically from the company’s systems and tailored to specific roles and needs

- All relevant metrics, such as order volume, price development or supplier quality failures which are pulled from the company’s systems and posted on dashboards for broader groups of stakeholders

- Advanced tools that map procurement savings within specific categories to respective line items in your company’s P&L. This ensures direct linkage between procurement performance and EBITDA.

- In addition to ERP data, add-on tools can be used to gather and analyse additional data points like staff training and the progress of employees’ skill levels.

3. Develop a solid data foundation by aligning data analytics and existing IT systems

a) Digital analytics

Digital analytics help procurement organizations to use their existing data in a much more efficient and insightful way. As a result, buyers can make much better business decisions than in the past and increase their business value contribution.

But to use data analytics effectively, organizations first need to prioritize the most relevant KPI’s for the dimensions (e.g. savings, quality, innovation, or risk) into which they want to gain insights. This defines required data points, sources, and types of digital analytics. For the implementation of these decisions within the procurement function – depending on the maturity of the organization - we typically recommend a small team of external experts to ensure a quick ramp-up and immediate results. Throughout the implementation, a highly capable advanced analytics team should be set-up.

b) IT systems

The digital procurement strategy can only be complete when addressing existing IT systems. They are the foundation and basis not only for data generation but also for nearly all new applications, including digitally driven activities such as the automated PR-to-PO process. In addition, these systems provide all data used for deeper analysis and hosts the main process and data stream of the department. Almost all digital applications need to access the existing systems and provide their inputs without hindering or harming the systems’ functionality. Thus, it is key to cover such considerations in the digital procurement strategy and to involve the IT department at an early stage.

Conclusion

Over the next few years, digital technologies in procurement will continue to play a more important role within leadership’s agenda and CPO’s will seek opportunities to boost procurement value with the help of digital. But to enhance operational performance significantly and to deliver increased business value, it is important that procurement organizations build a digital strategy that selects and implements the right tools.